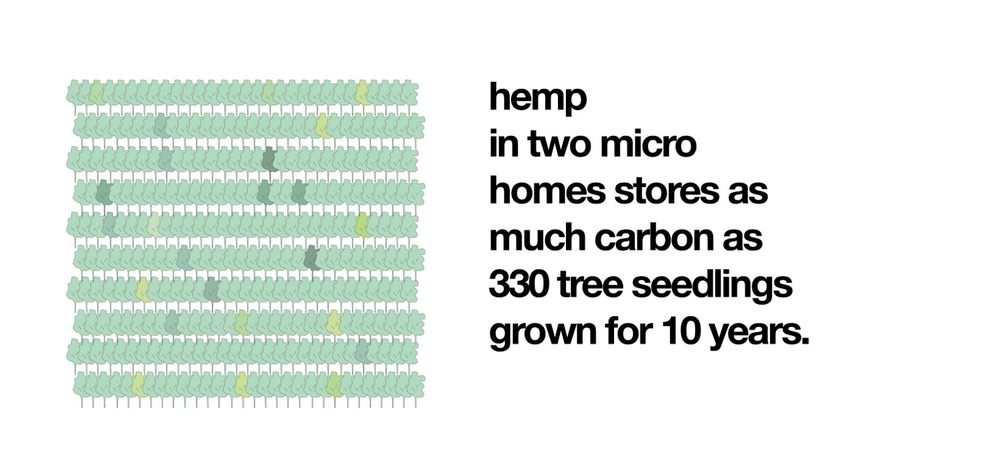

Hempcrete-insulated cabins at Wally Farms project sequestered as much carbon as 330 tree seedlings grown for 10 years. Photo Courtesy of Kaja Kühl.

By Kaja Kühl

This article is part of the Climate Action Lab at Wally Farms, a project diary to build a carbon negative dwelling –exploring architecture and design solutions that address the climate crisis. This article has been edited for length. read original HERE.

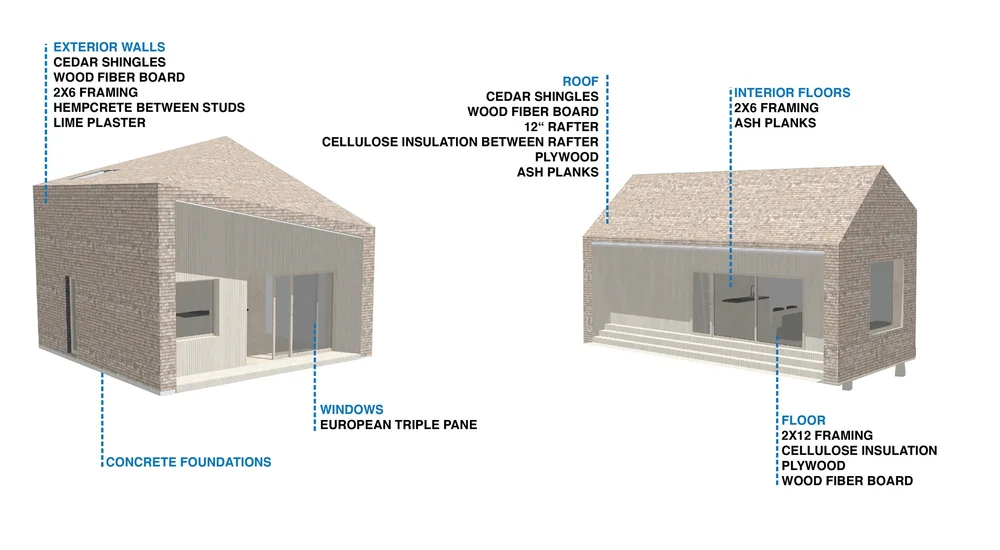

One of the biggest motivations in using hemp and lime as a construction material was our interest in building “net zero” or “carbon-negative” or “climate-positive” or “carbon-neutral”– there are a lot of different terms being used, ultimately, it is about achieving a balance between the carbon emitted into the atmosphere, and the carbon removed from it.

In architecture, it is about thinking of building materials as carbon sinks. Hemp is such a sink, because of the high amount of carbon it sequestered while growing. Estimates claim that hemp absorbs 2 metric tons of CO2 per acre, 5–10 times as much as trees because of its fast growth.¹ This CO2 is then stored in the building.

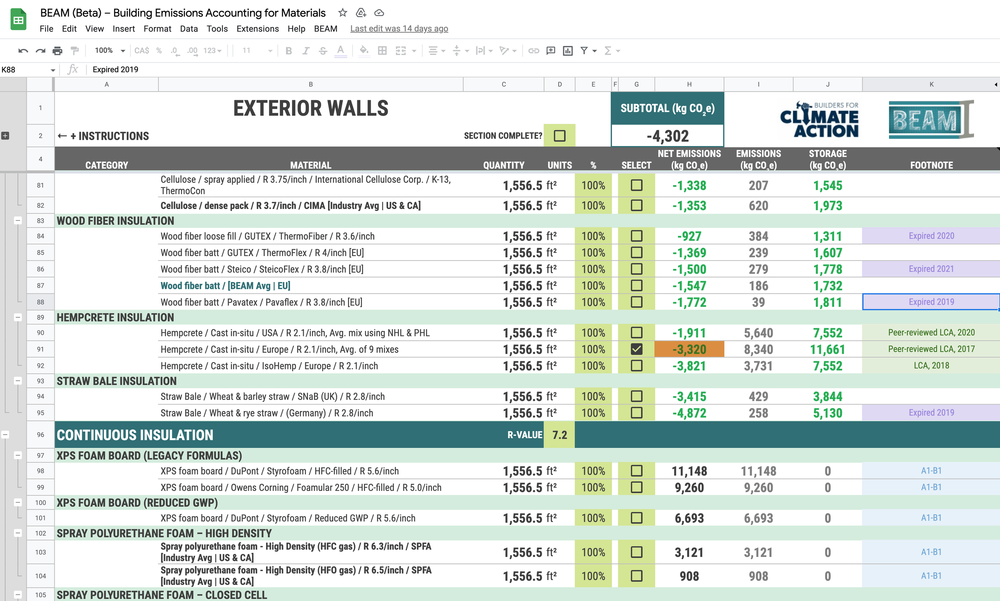

A number of software tools exist at various stages of development and/or use to help architects quantify embodied carbon in all kinds of materials. Few integrate “negative carbon” or carbon storage into their database. We worked with a beta version of the BEAM Estimator by Builders for Climate Action to input materials for envelope and framing.

Subscribe for HempBuild Magazine’s free newsletter

In its current form — a public beta version — it is a google sheet and pretty simple, which is its biggest strength in my view.

Screenshot of BEAM Estimator

Its ease of use makes it a great tool to quickly look up the difference between two materials and to get a general sense of embodied energy without having to study complex scientific Environmental Product Declarations (EPDs). Too often, we make material decisions based on aesthetics, warranty, functionality and of course — price. A quick look at this database lets you add the embodied carbon impact as a factor for choice.

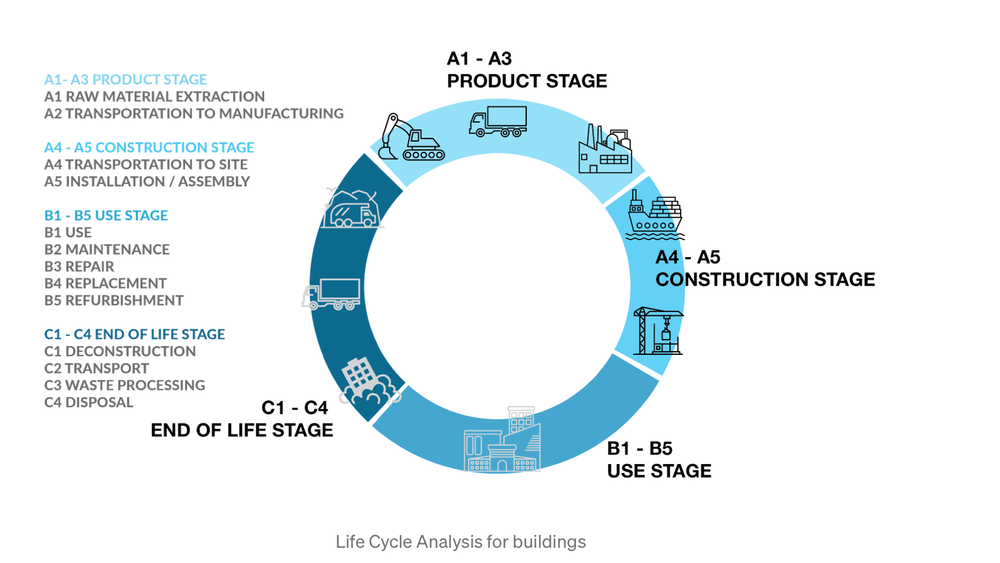

The BEAM estimator focuses on “cradle to gate” — the material emissions associated with producing a material (A1-A3 in a life cycle analysis).

Here are some of the reasons why:

-

Product emissions represent between 65–85% of the full life cycle emissions for most building materials, making A1-A3 the biggest source of emissions to address.

-

Product emissions are emitted now. They are emitted into the atmosphere before the building is built. To stay within 1.5 to 2.0˚ warming we need to reduce emissions now. Energy efficiency within the building will only help reduce CO2 in the atmosphere over a long time period.

-

There are meaningful differences in A1-A3 emissions between competing products, making it relevant to pay attention when choosing

Negative Embodied Carbon

So obviously the best part of using the BEAM estimator was inputting our buildings’ dimensions and seeing its embodied carbon value drop below or close to zero.

BEAM does this by subtracting the carbon-storing capacity of a material from the carbon emissions in phase A1-A3 using values from Phyllis 2, a databasecontaining information on the composition of biomass. When the carbon-storing value is higher than the emissions to harvest and process a material, its embodied carbon is negative.

Click here to go to our FREE online community.

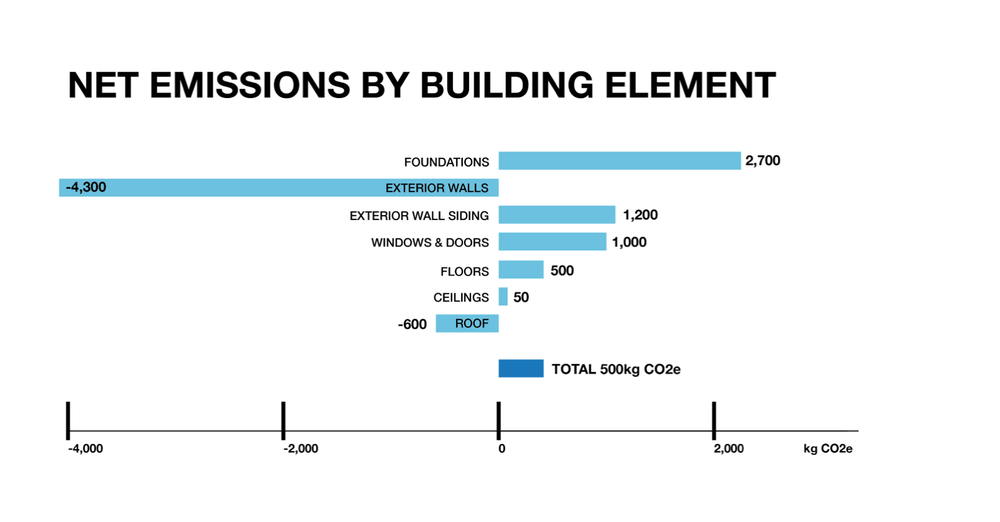

Soooo…. Here is what we found

Building elements included in the embodied energy calculation

Both homes’ embodied energy is about 500kg of CO2 equivalent, approximately the equivalent of using 56 gallons of gasoline.

The concrete foundation, while not big, was really hard to make up for in both micro homes. This again is a question of scale. We would have not used a lot more concrete for a three-story house, but would have installed a lot more biogenic material to balance the high emissions of the concrete.

Net emissions for hempcrete cabin (left) showed significant reduction in carbon footprint.

Hempcrete

The hempcrete did not disappoint, storing the greatest amount of carbon in both structures. Cellulose is also impressive without the additional health benefits that hempcrete provides. Ultimately, paying closer attention to embodied energy, be it through using more bio-based materials or materials processed with renewable energy is critical to reduce emissions in the critical short term setting buildings on a path to reducing emissions in their design and construction.

Comparison of embodied carbon in hemp with 330 tree seedlings using the the EPA’s Greenhouse Gas Equivalencies Calculator,

Kaja Kühl is a people-centered urban designer in Brooklyn, passionate about saving the planet. Adjunct Associate Professor at Columbia GSAPP @youarethecity

Please Support Our Classified Advertisers

••

Please Support Our Classified Advertisers ••

(To find out more about advertising CLICK HERE).

Help Wanted:

Training and Education

Publications

-

Hemp Building Directory 2022 – Guide to the International Hemp Building Industry

-

Available Now! “Hemp Buildings – 50 International Case Studies” by Steve Allin

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

Hempcrete installers/Insulation subcontractors

Lime Binder

Hemp Batt Insulation/Supplies

Green Builders

Hemp Building Engineers

Hemp Genetics

Professional Associations

Events

Originally published June 30, 2022 on Hemp Building Mag

https://www.hempbuildmag.com/home/measuring-carbon-footprint-hempcrete